- MACH3 CNC SOFTWARE MANUAL HOW TO

- MACH3 CNC SOFTWARE MANUAL INSTALL

- MACH3 CNC SOFTWARE MANUAL MANUAL

- MACH3 CNC SOFTWARE MANUAL LICENSE

It has enough features you may need for your operations.

Mach4 can also run machines with 6-axis but are available in many different versions as per your need of usage.įor hobbyists and small businesses, you can go for the "Hobby" version of Mach4. Now, we will configure Mach3 for operation with PoKeys devices.

Once connected, you can use the same 10-pin IDC cables with connectors as with PoKeys57CNC above.

MACH3 CNC SOFTWARE MANUAL MANUAL

Laz圜AM plug-in will help you build G-code files directly from. Follow the instructions in the PoExtBusOC16-CNC user manual on connecting it to the PoKeys57U or PoKeys57E device. You also have an option to add Laz圜AM as an add-on plugin. Like Mach3, Mach4 can also import and edit G-code files from most of the CAD software to control your CNC machine. You can also overcome the parallel port requirement by using the Smoothstepper mechanism to connect with your laptop or desktop without a parallel port.

MACH3 CNC SOFTWARE MANUAL INSTALL

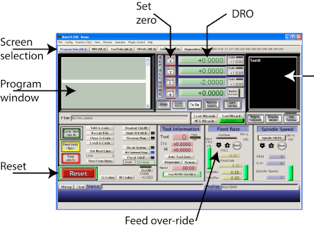

If you're using your computer itself as a controller, you'll need to use a PC with a parallel port and have to install the 32-bit version of Mach4 in such a case. When using an external motion controller, you can work with a laptop or desktop of your choice using a USB connection. But Mach 4 has a smoother UI than Mach3, which requires at least 512MB of graphics memory and 1GB of RAM for the program to load. It's made from scratch and Artsoft claims that Mach4 only uses less than 1% of Mach3's original program code. Hard Copies (a disk) of the downloadable content are available directly from a 3rd party.Mach4 is the latest version available in the Mach series and is made to stay on par with time by providing the users with more simplified controls. The Add-ons for Mill will only work with a licensed copy of Mach3 as this software is an Add-on, and not a stand-alone product. Simulation mode can be accessed by uninstalling (or not installing) the Parallel Port Driver. If a computer not connected to a machine is used to test code, please use Mach3 in Simulation mode – it will remove the 500 line limit.

MACH3 CNC SOFTWARE MANUAL LICENSE

Mach1, Mach2, and Mach3 may all be used on one computer, but only one version of each will co-exist on a single computer.Ī license is only required on the computer actually running a machine. For commercial users (anybody who uses the software to generate profit), we require a separate license purchase for each machine. Non-commercial users (aka hobbyists) are permitted to use one Mach license for as many machines as they require.

MACH3 CNC SOFTWARE MANUAL HOW TO

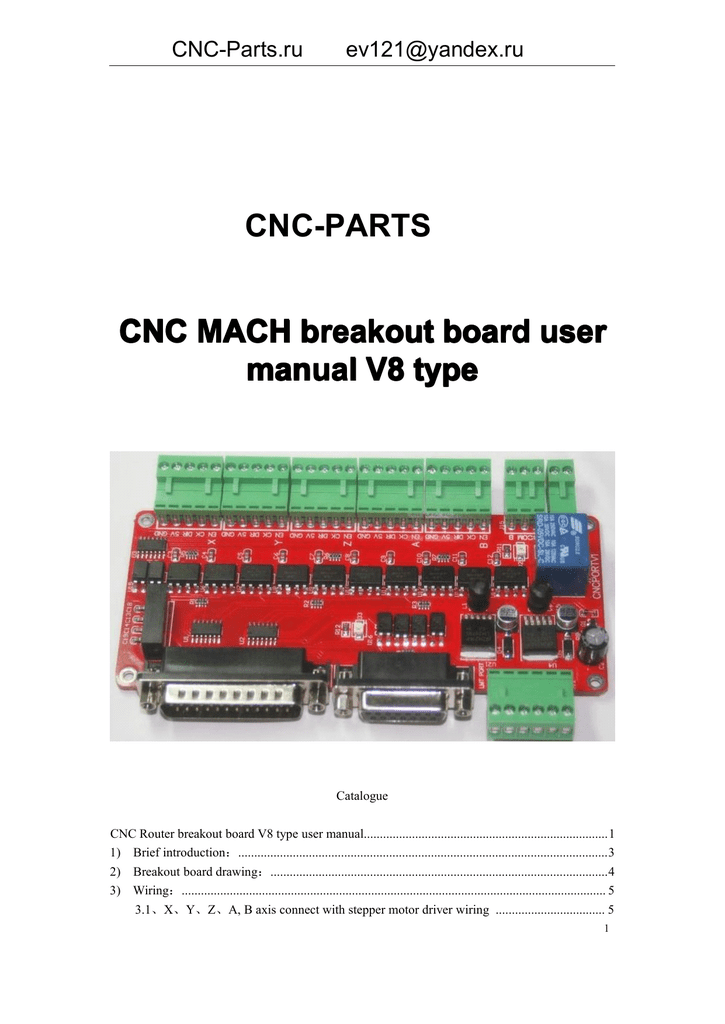

I KNOW how to make a CNC machine work faster and more reliably, because I have spent years learning how. You want a solution that is proven and you don’t want to waste your time searching the web to find out how to use it. 5.2 Stepper/Servo Motor Control Interface Connection 5.3 Spindle Control Output Port. Brief Description of the UC300 Motion Controller 2. If you are here on this page now it is because you want to make your CNC machine work faster and more reliably. Mach3 CNC Motion Controller Users Manual V2.

0 kommentar(er)

0 kommentar(er)